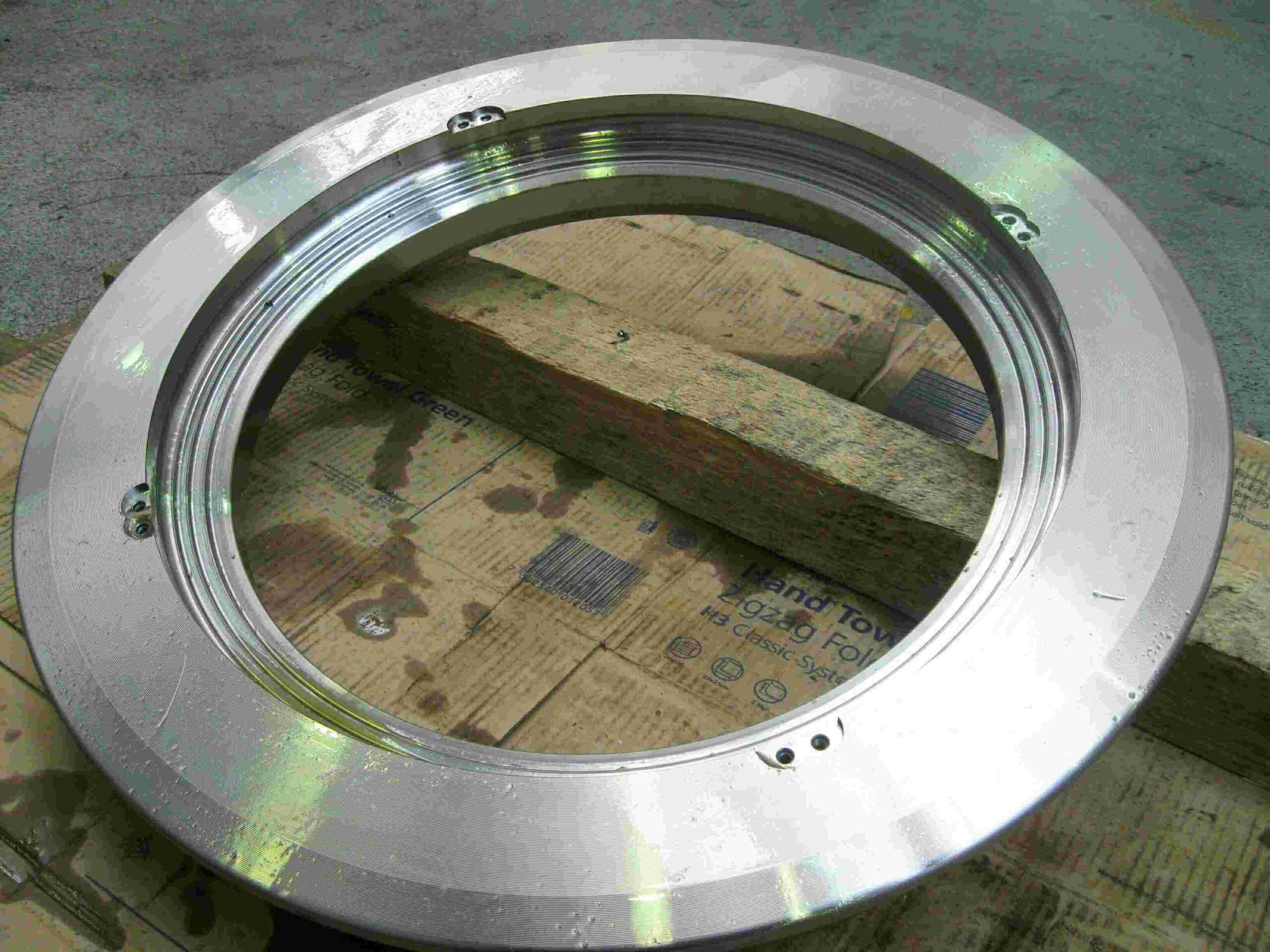

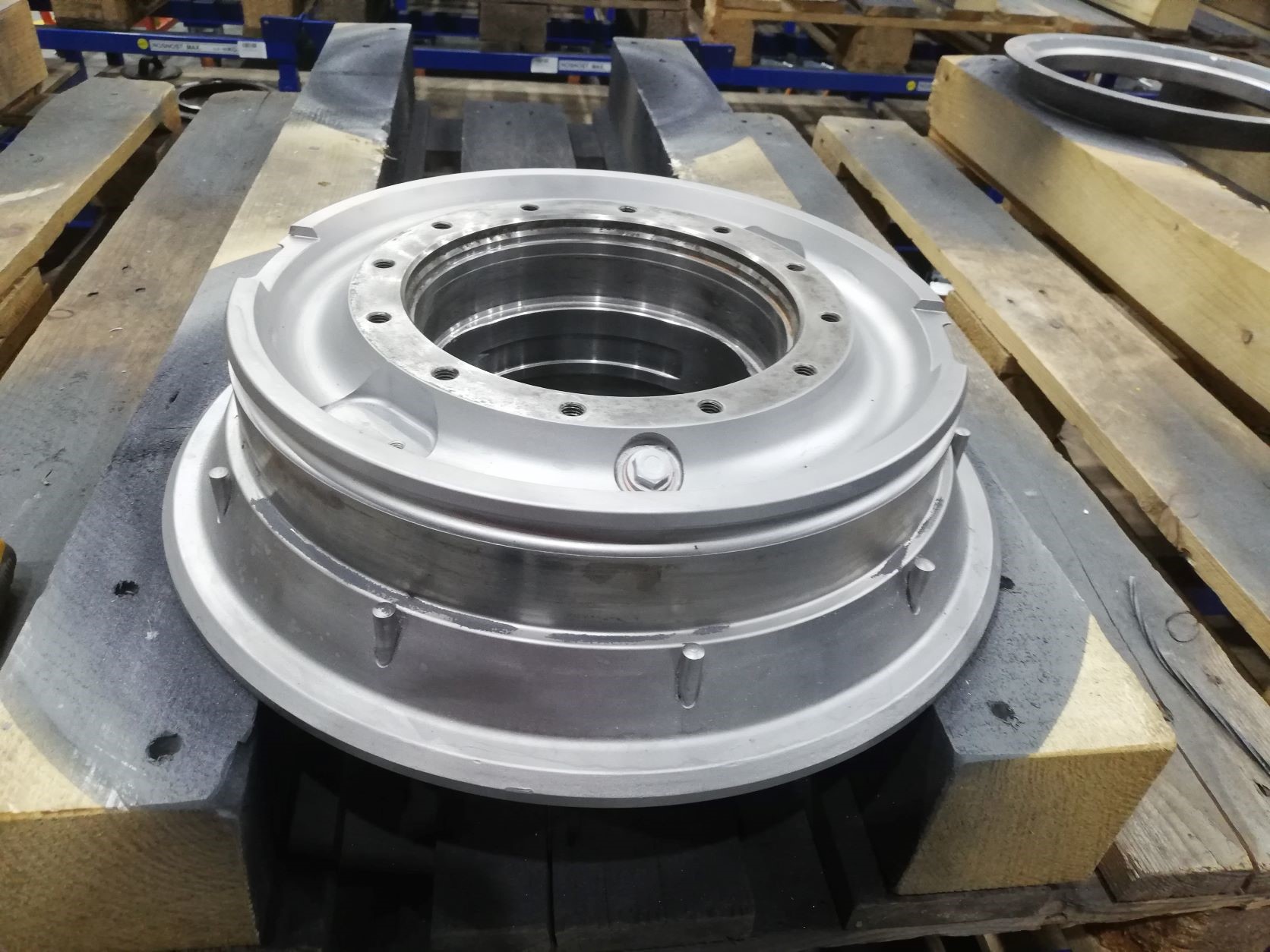

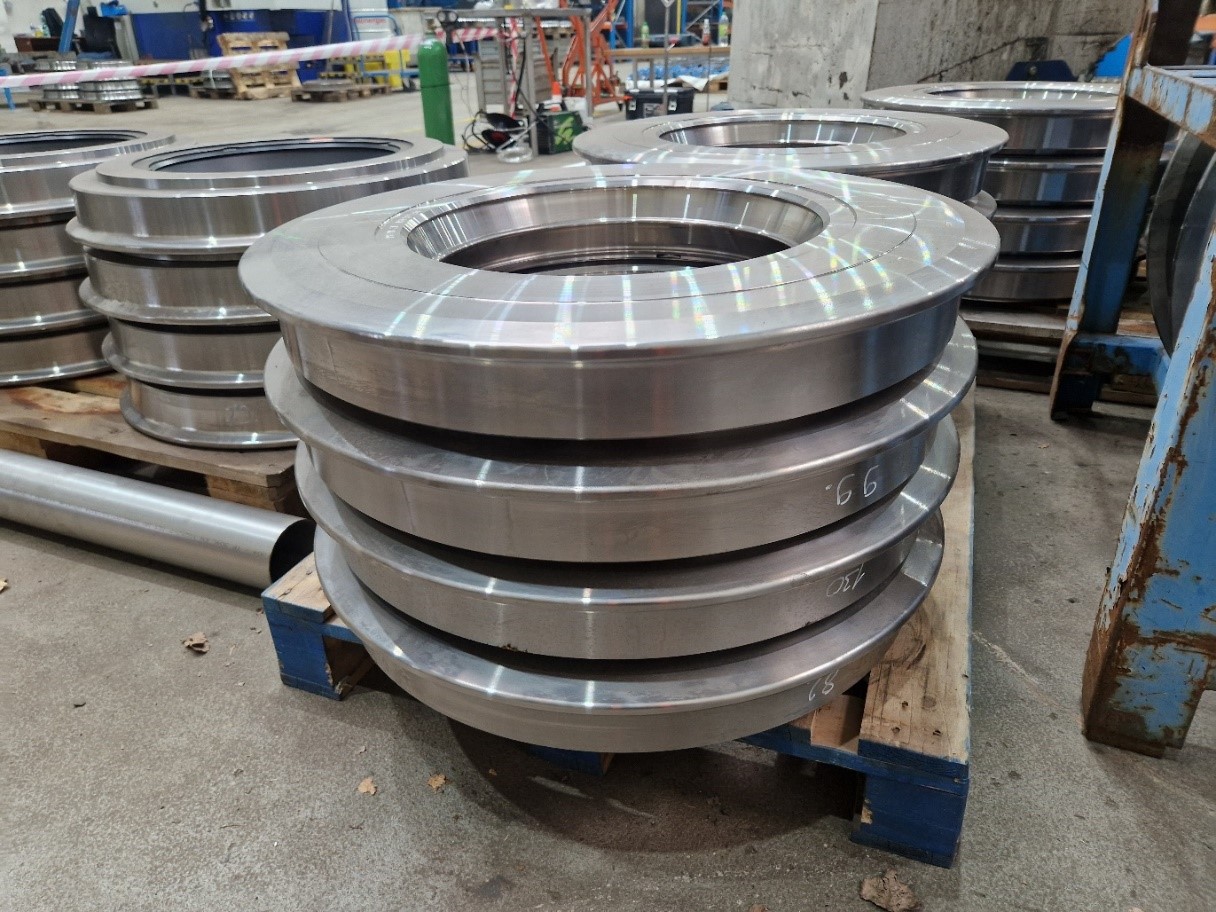

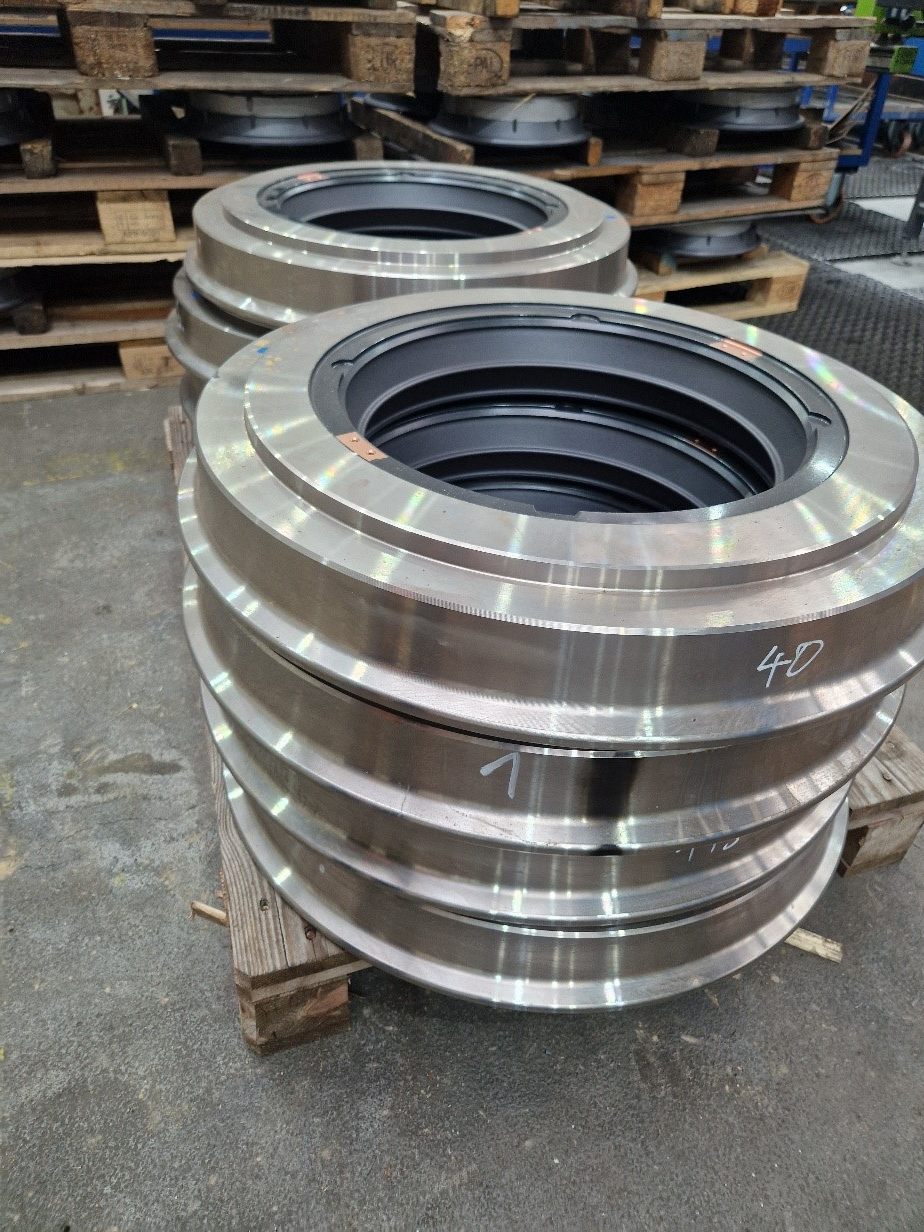

As part of our production program, we also supply new tram wheels and machined wheel tyres for tram vehicles in various profiles and types according to customer requirements. Wheels and tyres represent a significant segment of spare parts and we supply them for various types of trams. Spare parts are manufactured using the same strict standards, procedures and testing methods as original products. After the modern Škoda trams were put into operation, we expanded the production of wheels and wheel tyres not only for the original ČKD series vehicles, but also for new modern types of wheels and tyres since 2000. We currently produce various wheel profiles and wheel tyres for various types of trams with various running profiles in the amount of thousands of wheels per year, not only for transport companies in the Czech Republic but also abroad. As a standard, we supply them up to a diameter of 800 mm and a weight of up to 120 kg. We supply wheels and tyres completely machined with a running profile specified by the customer. The most commonly used material is B6 steel (tensile strength 920 – 1050 N/mm2; hardness 269 – 311 HB), but other grades are also possible (e.g. B7, C3).

For turning tram tyres and monoblock wheels, we use two vertical lathes – carousels with a rotary tool drive (C axis).

See catalogue:

Carousel parameters:

- max. rotating diameter 1400mm,

- diameter of the table clamping surface 1000mm,

- max. workpiece height 1200mm,

- max. workpiece weight 5000 kg.

Other options of Prazska strojirna a.s. in the field of production and renovation of tram wheels:

- production of tram monoblocks from 42CrMo4 material (drop forging),

- reconditioning of wheels:

o composite wheel,

o sprung wheel,

o surface treatment of wheel components:

– painting,

– removal of old paint in a blasting cabin (balloting), - o disassembly and pressing of sprung wheels.